Automation cells for industrial applications

Water Treatment Boards

Water, as a fundamental part of life, needs to go through the treatment process to guarantee to humans, animals, environment, processes, etc., the necessary quality to maintain the balance between its use and its care. For this purpose, it integrates mechanical, filtration, dosing, aeration, reverse osmosis and other processes that allow efficient water treatment.

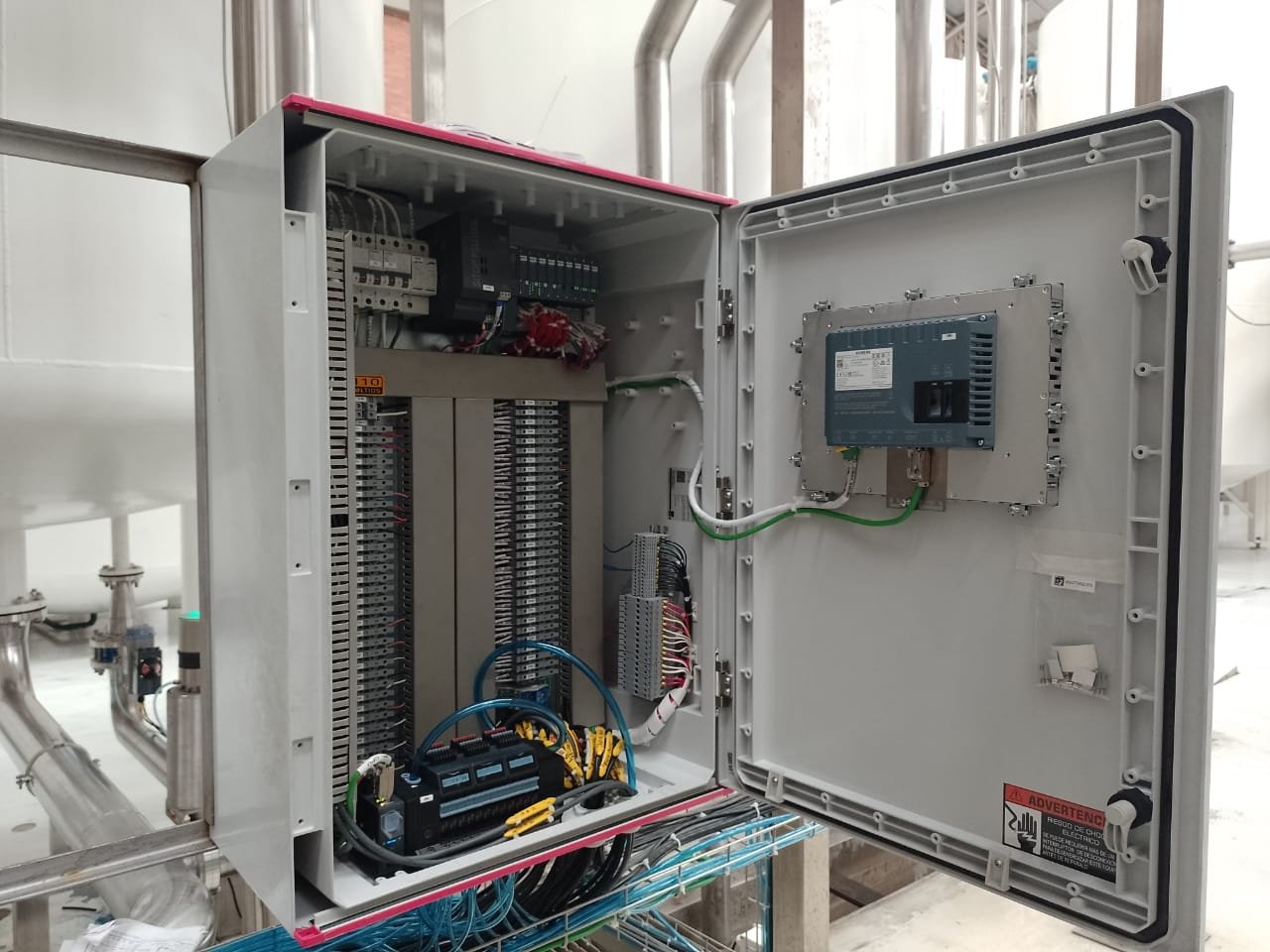

Within this great process, Automex SAS develops and integrates automated panels and cells for control and power, where we deliver a customized solution for each treatment plant, providing the level of automation that the project requires through the use of PLC programmable logic controllers and wiring logics.

We develop boards and cells for treatment plants such as:

Tailor-made automation projects for each industrial process

Pneumatic automation boards

In different types of industry it is necessary to operate pneumatic valves in order to perform some action such as moving an object, allow the passage of a fluid or perform some work with a movement, for this in many occasions we can find pneumatic valves.

Within the product portfolio of Automex SAS we have developed boards for the control of pneumatic valves, this type of board has a controller that generates an electrical or communication signal which is received by a solenoid valve that is responsible for converting it into a pneumatic signal available to the end customer according to their needs.

Data acquisition boards

Nowadays we have access to information immediately, the whole world has been in constant change where every piece of information is important to make a decision, we can have a statistic or a trend of this information.

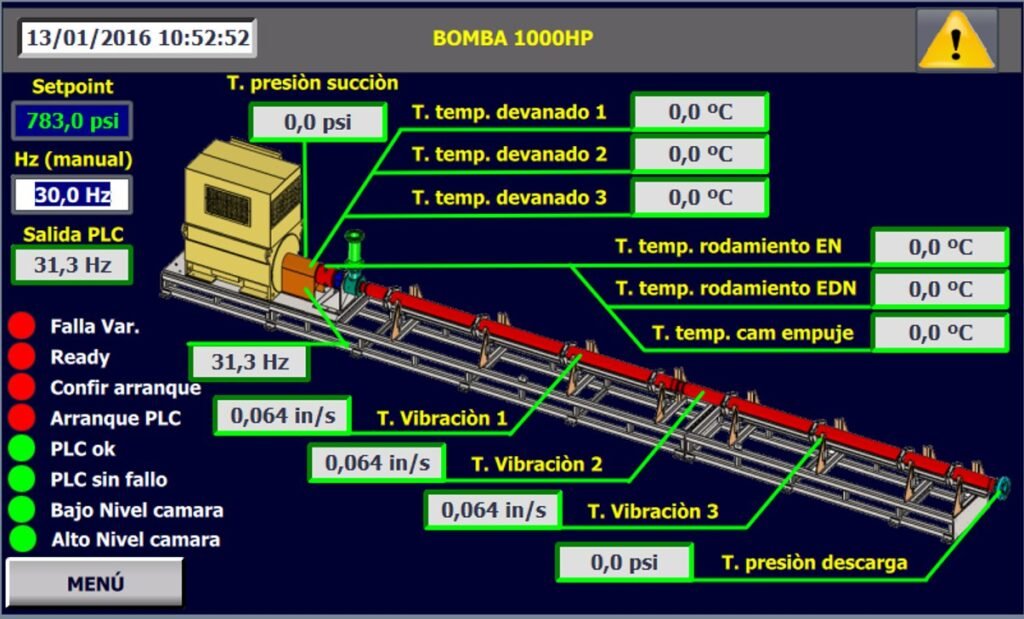

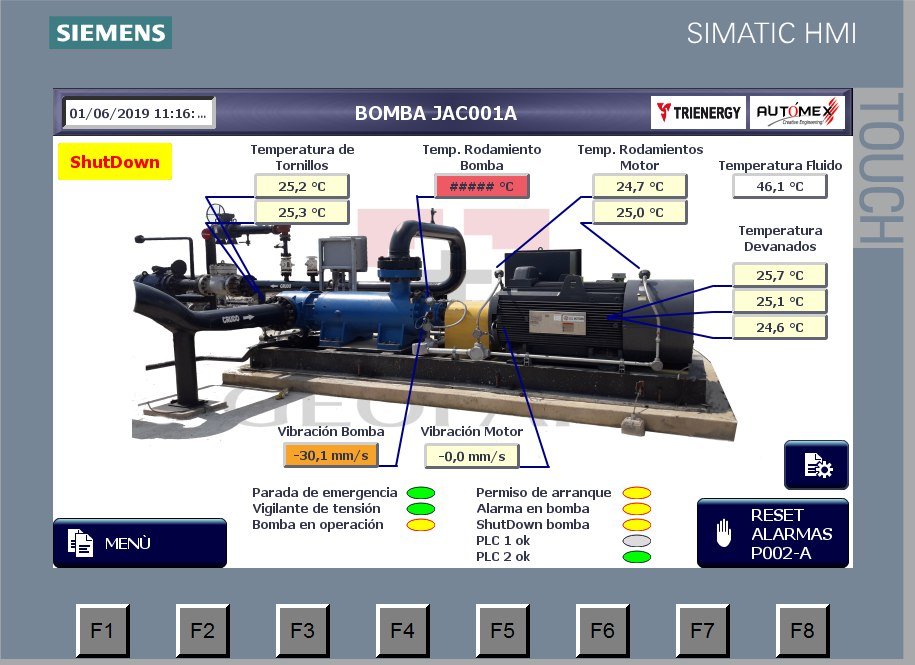

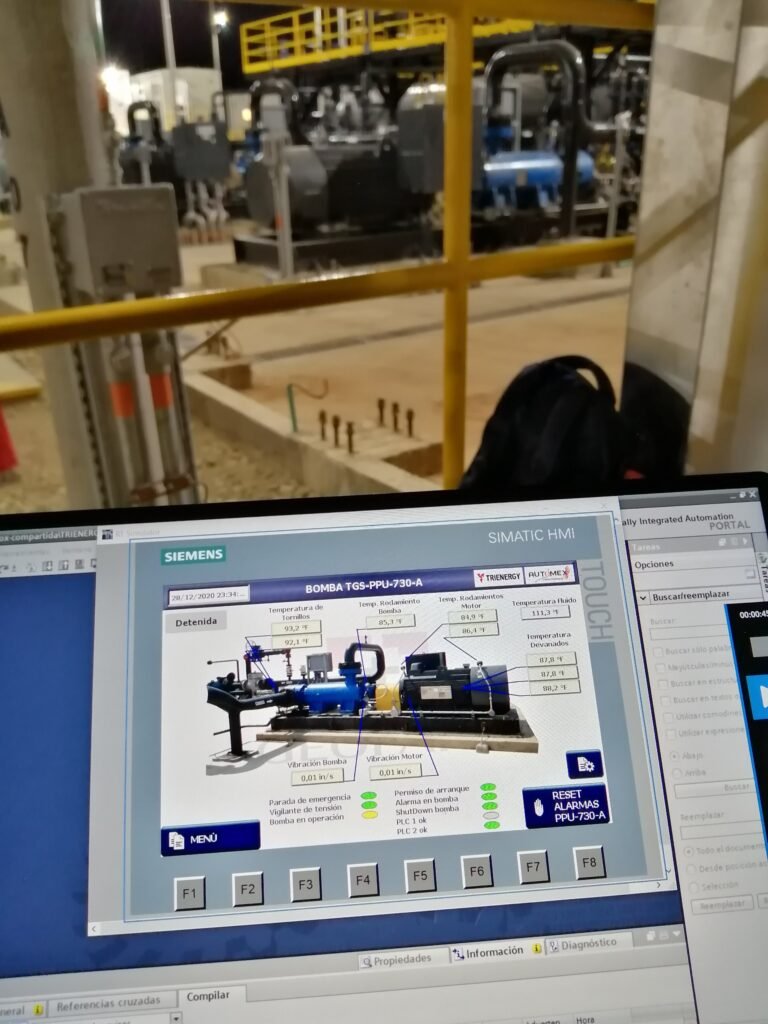

There are processes where it is necessary to monitor a variable such as the temperature of an oven, the flow of a pump, the current of a motor, the state of a valve, the pressure of the hydraulic system, the level of product inside a tank, etc. and in turn we need to take it to a control center, indicate it in a device, send an alarm, warn if the equipment requires intervention or perform some action.

For this Automex SAS develops boards with the ability to receive these signals through sensors, process this information, perform one or more actions and additionally send this information to different systems through communication regardless of the distance.Decentralized periphery boards

In the industrial world, determining the best location for the main control panel is sometimes a bit complicated due to the distances that the cables must travel within the plant, the cost increases depending on the number of signals, the spaces can be very small where the conductors must travel, in case of breakage of a conductor it is a time consuming task to determine the point of damage, signal loss can be caused by the distances, etc.

To avoid these problems in Automex SAS we develop PLC systems and other industrial components that have the possibility of linking to the PLC the signals that are necessary from a long distance by means of communication, where it is necessary to install a much smaller board that is responsible for receiving these signals with less distance and sends them to the main PLC which processes them and by this same means can send an action to maintain controlled operation.

Hot&StandBy Boards

There are automated processes that constantly require a backup either of the information or the maintenance of a process, these processes are critical for the company either because human lives depend on them as in hospitals, large amounts of money may depend on them as in banks or loss of raw materials may depend on them as in the industrial sector.

Automex SAS develops Hot&StanBy systems to meet these needs, they are boards that have dual CPU signal processing, where these constantly exchange data and becomes like a "mirror" of each other so that if one of these goes into failure the other takes control thus avoiding the loss of information or in the worst case the stoppage of a process.