Hydrosmart

L932 pro

The evolution of HydroSmart, L932Pro, allows users to interact in an agile, practical and very intuitive way with the pumping system.

- Full color HMI Touch screen for easy programming and clear system information.

- Possibility to adjust the alternation of the pumps.

- Measurement of energy consumption per pump in Kw/H.

- It has all the protections, advantages and connections similar to the HydroSmart L9 Plus.

- Modbuss RTU / RS485 communication port - for BMS monitoring and control.

- Possibility of installing a 4G/WIFI/GPRS communication module (NOT INCLUDED).

Weight

Size

RETIE Certificate

Immediate Availability

IP54 protection

0.5 to 15 hp

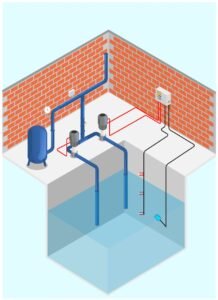

Differential Pressure Equipment

HydroSmart intelligent controllers ensure the correct operation of the differential pressure system of one or two pumps, performing alternation, addition and backup in case of pump failure.

Among the functions for the differential pressure system, the HydroSmart controller has a dry pump protection function when the suction well runs out of water, upon detection, it generates the fault, stops the pumps and starts its counter function to reset in case the water column is restored.

– Use with pressure switches.

– Use with 4-20 mA pressure transducer.

On-demand alternation, backup and addition function.

– Dry pump protection by float, electrodes or without them

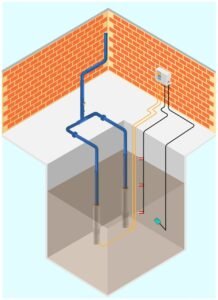

Drainage Equipment

Protect your sewage, rain or groundwater drainage system by using HydroSmart controllers, which feature advanced protections to prevent damage from clogging, voltage changes and other variables.

HydroSmart controllers are the ideal equipment to operate drainage systems, since they provide integral protection to submersible pumps, giving the option to operate with different types of sensors and monitoring their status either via Modbuss RS485 protocol or remote control panel wiring.

– Use with floats or electrodes.

– Use with 4-20 mA level transducer

– Use for submersible pumps with internal float.

On-demand alternation, backup and addition function.

-Electronic alarm buzzer and alarm connection facility

Lifting Equipment

In lift systems, HydroSmart controllers allow tank filling to be controlled using different types of sensors, ensuring versatility in the operation of the water pumping system.

One of the advantages of HydroSmart controllers is to protect the water suction well without the need for a float or sensor in the well. Its current-based electronic protections allow to program the protection values according to the pumping system’s needs.

-Use with 4-20 mA level transducer.

– Toggle only function.

-Alternation and addition function on demand.

-Dry pump protection by float, electrode or without them.

Main Features

- Manual / Automatic Selector Switch

- Memory recovery when deenergized

- Resetting of work in case of failure or vacuum events

- Display of pump operating time

- Display of the last five faults of each pump

- Overload Protection

- Motor protection Stuck

- High / Low Voltage Protection

- Dry working protection

- Phase loss protection

- Phase reversal protection

- Phase unbalance protection

- Pump cycling protection

- Pump shaft anti-oxidation protection

- 1NA external siren connection facility

- Modbuss RTU communication port

- Easy programming of protection ranges

- Receives signals from NO thermistors - one per pump

- Automatic calibration button

- Pump enable or disable function

- Lock function of operating buttons

With Hydrosmart controllers

Control your pumping systems as wishes!

Float/electric level float

Pressure switch / pressure switch

Level electrodes

Pressure transmitter 4-20 mA

Hydrostatic level transmitter 4-20mA

Learn how to program the Hydrosmart l932 plus

Easily learn how to program Hydrosmart controllers to your needs.